Description

Details:

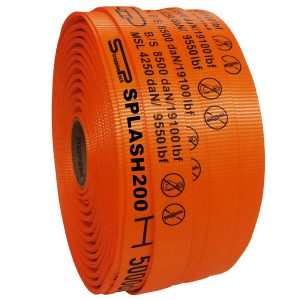

Flexible ratchet lashing strap is made of 100% high tenacity polyester yarn according to DIN EN 12195-2 and it is easy to be used.

Lashing strap make transportation and material flow cost-effective and are recommended for load securing as it can resist high drag, protect the surface, have long durability and light weight. With lashing straps, loads can be strapped, kept together and secured on transport vehicles. They are rot-resistant, rust-free, hardly absorb humidity. So they are extremely firm and can protect goods against abrasion. Ratchet lashing strap is relatively light. So it can be fitted quickly and easily.

According to different loading place, different categories of ratchet buckle can be chosen. According to the width of webbing assembled to it, there are sizes of 1”, 1 1/16”, 1.5”, 2”, 3”, 4”. According to its appearance and additional functions, every specification has lots of types.

Ratchet buckle is laboursaving by gear and handle. During using, ratchet strap can tighten goods through a few times of strength when you force the handle.

Different specifications of ratchet buckle have different breaking strength. Its safety factor is high. And our ratchet straps pass TUV CE, GS certification.

Applications:

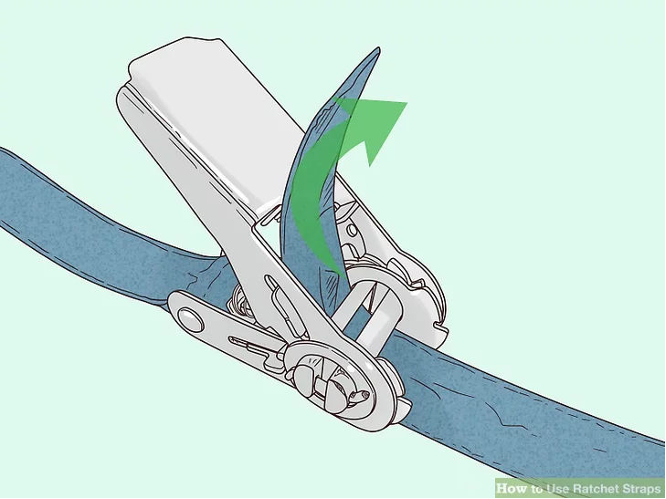

Ratchet straps are fasteners used to secure cargo during transportation. When it is used correctly, these straps can support many different weights and cargo sizes. In order to use the ratchet straps properly, pass the strap through the mandrel and then crank the ratchet to tighten it. To release the strap, press the release tab and open the ratchet.

How to use ratchet lashing strap:

1. Threading a Ratchet Strap

The release catch is also known as release lever. It is a smaller handle that disengages the ratcheting handle. It’s located in the center of the top movable piece of the ratchet. When you pull up the release catch and flip, the ratchet will fully open. Set the open ratchet on a table so that the spiked wheels face upwards.

2. Thread the strap through the bottom of the ratchet.

The slot at the bottom of the ratchet is known as the mandrel holds the length of the strap. To thread the strap, start from underneath the ratchet and push it up through the mandrel. The threaded strap should then lay straight and the length of it overlapping with the second strap on the other side of the ratchet.

3. Releasing the Strap

Pull and hold the release tab. This will override the ratcheting function and release the lock. The release tab should be easy for access and located on the top of the ratchet.

Pull and hold the release tab to close the ratchet again. Locate the release tab once again and hold it down while you flip the ratchet closed. This will keep the ratchet in locked position until it is ready to be used to again.

If you can’t locate the release tab, check your operation instruction manual.

Tips

Ratchet straps also have a wide variety of sizes and end fittings to secure many different sizes of loads.

Choose the length you need and the type of hardware that will work best, such as flat hooks, snap hooks, wire hooks, grab hooks, s-hooks, and so on.

Ratchet straps are rated by their weight capability, ranging from a light strap for 300 pounds (140 kg) to a heavy-duty strap that can support up to 10,000 pounds (4,500 kg). Make sure to weigh your cargo so you can choose the correct straps to support it.

Reviews

There are no reviews yet.