Strappings are classified into steel strapping, pp strapping, PET strapping, composite cord strapping, hot melt strapping and woven cord strapping. They have different performances due to their differences on material and production process.

Steel Strapping:

High hardness and hard to use, easy to occur burand get rusty, rough surface and easy to hurt finger, not very convinient for packing

PP Strapping:

Good plasticity, lighter material, bright in color, it is soft and easy to use, but low breaking strength and large elongation, easy aging and too loose to continue tight. It is just used for packing carton and lighter objects.

PET Strapping:

The breaking strength is higher than PP strapping, the aging degree is better than PP strapping, but the elongation is too large and the breaking strength is much lower than composite strapping . It is just used for packing carton, plastic film and light objects.

Composite Strapping:

From agriculture, landscaping, automotive, printing, light building products, to baling corrugated and plastic for recycling, bonded cordstrapping is your best solution.

High strength, as strong as steel ;

Portable and soft, the weight is less than 20% of iron;

Have no sharp edge, safe for users and goods;

Will not rust, rot or deformation;

Wide applicable temperature and climate, can work normally at -40 ℃ -130 ℃;

High linear and system tension;

Can buffer the enormous impact in the transportation;

Good flexibility, will not deformation, can easy to pass through the goods and easy to fold;

It is easy to use and waste less, safe to use and dismantle(recycled).

Woven Strapping:

Width 13mm and up

Polyester strapping retains excellent tension on rigid loads. It also has excellent recovery properties to help a load absorb impact without the strap breaking.

Woven poly strapping won’t stain or rust like steel strapping can.

The soft nature of poly strapping won’t damage the bundle being secured.

The polyester strapping won’t snap or break causing injury.

It is lightweight and much easier to work with and dispose of.

Both woven polyester and the composite strapping maintain its shape even under rigorous weather conditions.

Resistant to high temperatures, ultraviolet rays and moisture.

Polyester strapping can be printed.

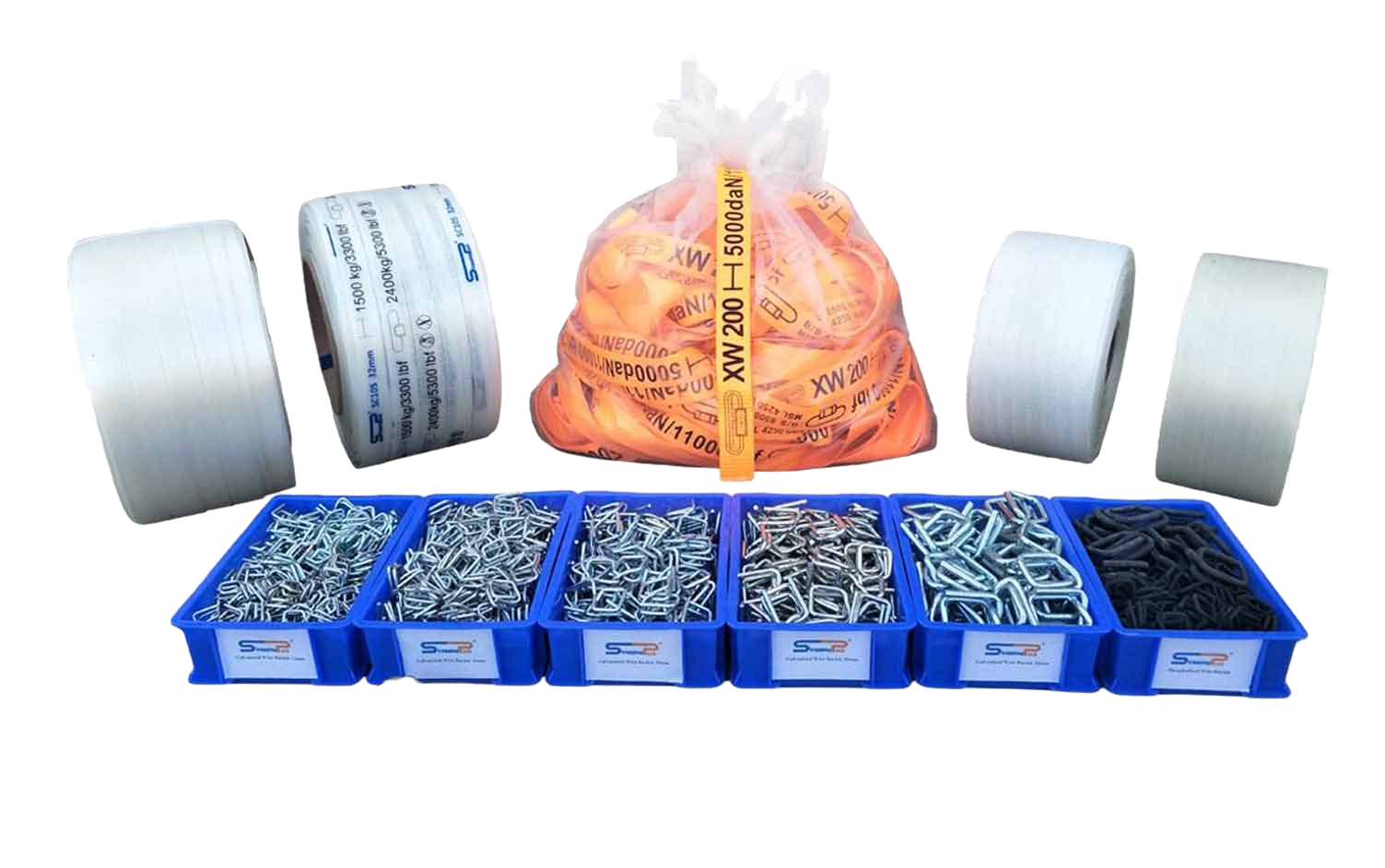

Polyester lashing strap:

Width 25mm and UP

Safe and easier to apply than steel with a great deal more versatility and shock absorbency

Saves time and expense when compared with other methods i.e. steel banding, ratchet straps, wire, shoring/bracing with timber, welding etc

Woven Polyester Lashing is easily dispensed from the bag

Simple to use – all that is required is the strap, buckles and the tool

Versatile – the continuous length which is contained in the bag enables the user to make-up straps to desired lengths, greatly reducing wastage of materials and time

Safer for the recipient to unfasten at destination

Easy disposal

Hot Melt Strapping :

No damage to delicate surfaces since it is a textile material

No corrosion & easy handling

Low investment costs

Small, manageable system

Re tensionable in case of volume loss of the packaging good

No risk of injury for shippers and consignees in using or opening the strapping

High breaking load, in linear and system

Dynamic transport movements are absorbed by the elasticity of the strapping

Easy disposal

Weatherproof (UV radiation)

Available width 9mm to 32mm ( 1/3” to 1 1/4” )

Linear breaking strength available from 160 to 1170 daN

The best solutions for safely and easily packaging is composite cord strapping, woven cord strapping, hot melt strapping or polyester woven lashing strap.